Infrared paint drying is a revolutionary technology for automotive and industrial repairs, offering faster curing and drying times compared to traditional methods. Its benefits include reduced solvent evaporation, rapid cross-linking for stronger bonds, and consistent heating for superior results. Ideal for detail work on vehicles like Mercedes Benz, dent removal, and restoration projects, this method significantly speeds up the painting process, enhances finish quality, and decreases vehicle stay times in collision repair services, ultimately increasing client satisfaction. However, successful implementation requires meticulous preparation, environmental control, strategic positioning of infrared heaters, and close monitoring to prevent damage and ensure worker safety.

Infrared (IR) paint drying is a revolutionary technology transforming the coatings industry. This innovative process accelerates cure times, reducing drying periods and energy consumption. Understanding IR paint drying involves grasping its unique heat transfer mechanism, making it ideal for diverse applications, from automotive finishes to industrial coatings. This article delves into the benefits, explores real-world uses, and offers best practices to help professionals harness the power of infrared paint drying effectively.

- Understanding Infrared Paint Drying Technology

- Benefits and Applications of Infrared Paint Drying

- Best Practices and Considerations for Effective Use

Understanding Infrared Paint Drying Technology

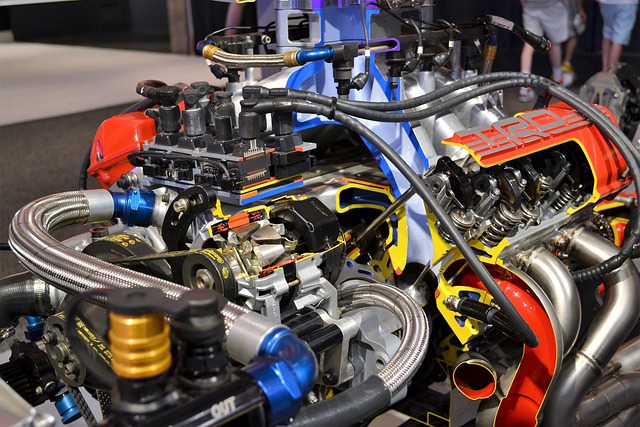

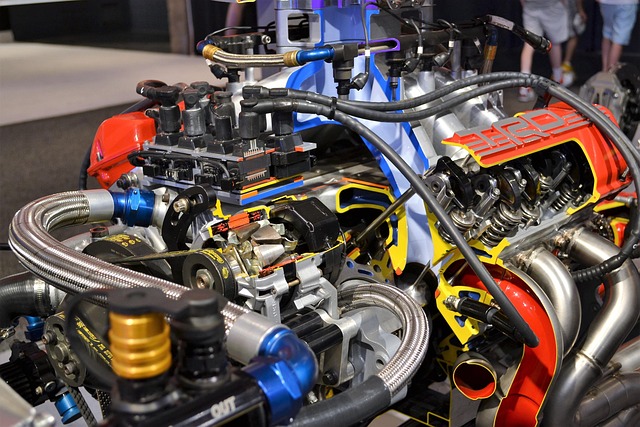

Infrared paint drying is a cutting-edge technology revolutionizing the automotive and industrial sectors. This innovative process utilizes infrared radiation to accelerate the curing and drying of paint, offering numerous advantages over traditional methods. By emitting heat at specific wavelengths, infrared technology can quickly evaporate solvents and promote rapid cross-linking of the paint, resulting in faster drying times.

This technology is particularly beneficial in auto detailing and Mercedes Benz repair, where efficiency and precision are paramount. Unlike conventional drying methods that rely on ambient temperature, infrared paint drying ensures consistent and controlled heating, minimizing the risk of paint imperfections or uneven curing often associated with slower drying processes. Its effectiveness is also evident in dent removal and restoration work, as it can speed up the overall repair process while maintaining high-quality outcomes.

Benefits and Applications of Infrared Paint Drying

Infrared paint drying offers a multitude of benefits for both professional and DIY enthusiasts in the field of vehicle repair. By utilizing specialized infrared heaters, this innovative technique significantly reduces the time required for paint to dry and cure compared to traditional methods. This not only expedites the overall painting process but also enhances the quality of finishes, ensuring faster turnaround times for collision repair services and automotive body shops.

The applications of infrared paint drying are vast, particularly in demanding sectors like vehicle repair. Its ability to provide a consistent and controlled heating environment makes it ideal for achieving precise results in complex projects. Whether for minor touch-ups or complete overhauls, this technology streamlines the painting process, allowing automotive body shops to efficiently manage their workload and meet customer expectations. For instance, in collision repair services, infrared paint drying can dramatically reduce the time a vehicle spends in the shop, ultimately contributing to higher client satisfaction.

Best Practices and Considerations for Effective Use

When utilizing infrared paint drying for tasks like car body restoration or vehicle paint repair after a collision, best practices dictate prioritizing proper preparation and environmental controls. The surface to be treated should be clean, free from grease, dust, and debris to ensure optimal absorption of infrared energy. A controlled environment is crucial; maintaining a temperature range suitable for the specific paint product is vital, as excessive heat can damage the finish or substrate. Proper ventilation is also essential to prevent the buildup of volatile organic compounds (VOCs) and ensure safety for workers.

For effective results in car collision repair or vehicle paint repair projects, uniform heating is key. Positioning the infrared heaters at strategic angles and maintaining consistent distance from the surface helps achieve even drying without hot spots. Additionally, monitoring the drying process closely allows for timely removal of the heat source once the paint has reached the desired level of cure, preventing potential over-drying or distortion. Regular inspection ensures that the finished product meets high standards of quality and aesthetics in car body restoration projects.

Infrared paint drying is a revolutionary technology that significantly enhances traditional painting methods. By understanding its benefits, from faster drying times to improved surface quality, you can harness its potential in various applications. Best practices, such as using suitable infrared systems and ensuring proper environmental conditions, will ensure optimal results. Embracing this innovative approach not only streamlines painting processes but also opens doors to new possibilities in the industry, making it a game-changer for professionals and DIY enthusiasts alike.