Infrared paint drying technology revolutionizes car body repair, significantly speeding up traditional drying processes from hours to minutes. This innovative approach uses focused infrared heat, enhancing workshop productivity, minimizing human error, and ensuring consistent results. Its rapid drying capabilities streamline car damage repairs, reducing customer downtime and optimizing workshop capacity. Effective for various auto maintenance tasks, it ensures vehicles are restored faster and more effectively to their pre-damage condition. Additionally, infrared paint drying is energy-efficient, cost-effective, and environmentally friendly, making it an appealing choice for collision and auto repair shops aiming to optimize processes and shrink their carbon footprint.

Infrared paint drying is transforming the automotive and industrial finishing landscape. This innovative technology offers significant advantages over traditional methods, revolutionizing shop operations. By speeding up the paint drying process, infrared systems cut down on valuable time and boost productivity. With enhanced efficiency, reduced labor costs, and minimal waste, shops can optimize workflows and achieve superior surface quality and durability for every paint job. Discover how infrared paint drying is the game-changer it’s cracked up to be.

- Speeding Up Paint Drying Process

- – Advantages over traditional drying methods

- – Time savings and increased productivity in shops

Speeding Up Paint Drying Process

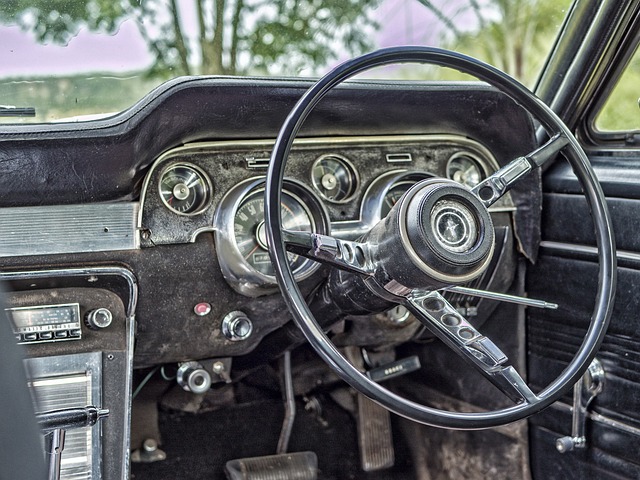

The use of infrared paint drying technology has revolutionized the way shops handle car body repair and auto maintenance tasks. Unlike traditional methods that rely on ambient air temperature, infrared paint drying speeds up the process significantly. This is achieved through applying focused infrared heat to the painted surface, which reduces drying time from hours to minutes. Not only does this efficiency enhance productivity in workshops, but it also minimizes the risk of human error and ensures a more consistent end result.

Furthermore, the rapid drying benefits extend beyond just convenience. In car damage repair, where time is of the essence, infrared paint drying can help streamline the entire process, reducing downtime for customers and optimizing workshop capacity. This technology is particularly useful in handling various auto maintenance tasks, from minor dents and scratches to more extensive repairs, ensuring that vehicles are restored to their pre-damage condition faster and more effectively.

– Advantages over traditional drying methods

Infrared paint drying offers a significant advantage over traditional methods, especially in collision repair and auto repair shops. Unlike conventional heating techniques that rely on air circulation, infrared technology directly heats the surface of the paint, accelerating the drying process dramatically. This not only reduces the time required for repairs but also minimizes the risk of uneven drying or surface imperfections that can occur with slower methods.

Furthermore, infrared paint drying is more energy-efficient, which translates to lower operational costs for auto repair services. By concentrating heat directly on the paint, it minimizes energy waste and the associated environmental impact. This makes it an attractive choice not just for collision repair but also for any auto repair shop looking to streamline its processes and reduce its carbon footprint.

– Time savings and increased productivity in shops

Infrared paint drying is a game-changer for any vehicle body shop or auto bodywork facility. By employing this innovative technology, shops can achieve significant time savings and boost overall productivity. The process uses infrared heat to accelerate the drying and curing of paints, eliminating the need for lengthy waiting periods between coats. This not only reduces the total time required for paint jobs but also allows technicians to handle more vehicles in a shorter span, increasing shop capacity and customer satisfaction.

Furthermore, infrared paint drying can enhance the quality of auto collision repair work. The precise heat application ensures even drying, minimizing the risk of blotchy or uneven finishes that can occur with traditional drying methods. This precision contributes to the overall aesthetics and long-term durability of repairs in a car collision repair setting, making it an invaluable asset for any shop looking to stay competitive in the market.

Infrared paint drying is a revolutionary technique that significantly enhances the painting process in shops. By adopting this technology, businesses can expect substantial time savings and improved productivity, making it an essential consideration for any modern workshop. Its advantages over traditional methods are undeniable, offering a faster, more efficient way to dry paints without compromising quality. This innovative approach ensures that shops can complete projects promptly, meeting client expectations and staying competitive in the market.