Infrared paint drying is a cutting-edge technology revolutionizing automotive restoration by speeding up paint curing processes compared to traditional methods. It efficiently converts electrical energy into heat, minimizing thermal damage and enhancing finish quality. Its precision heating offers time and cost efficiencies, reducing repair shop downtime and improving customer satisfaction, especially for Mercedes-Benz repairs. This method dramatically cuts costs and expedites bodywork processes, with a 20% labor expense reduction in one case study, resulting in superior paint adhesion and finishes.

Infrared paint drying is transforming the way we approach repair and maintenance, offering a game-changing solution to reduce costs and expedite projects. This cutting-edge technology leverages the power of infrared radiation to cure and dry paints quickly, eliminating traditional drying times. By understanding how infrared works and its numerous advantages, professionals can significantly cut repair costs and enhance efficiency. Explore these benefits and see real-world results in our comprehensive guide.

- Understanding Infrared Paint Drying Technology

- Advantages of Using Infrared for Drying Paint

- Reducing Repair Costs: A Case Study

Understanding Infrared Paint Drying Technology

Infrared paint drying is a cutting-edge technology revolutionizing the way we approach vehicle bodywork and automotive restoration. Unlike traditional drying methods that can be time-consuming, this innovative process uses infrared radiation to speed up the curing of paint and coatings on various surfaces. By converting electrical energy into heat, infrared lamps efficiently raise the temperature of the paint, ensuring faster drying times without compromising quality. This technology is particularly beneficial in body shop services, where minimizing downtime is key to maintaining efficient operations and customer satisfaction.

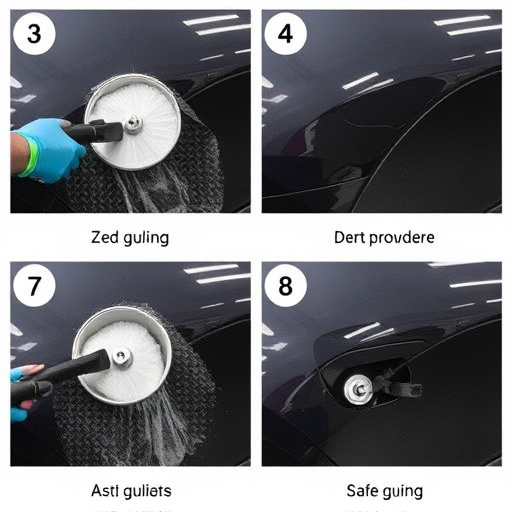

The precision and control offered by infrared paint drying are significant advantages. It allows for targeted heating, ensuring that only the painted areas are exposed to intense heat, while the underlying materials remain cool. This selective approach reduces the risk of thermal damage to sensitive components, often found in vehicle bodywork. As a result, it not only expedites the repair process but also contributes to the longevity of the vehicle’s finish, making it an attractive solution for both professional mechanics and DIY enthusiasts looking to restore their automotive masterpieces.

Advantages of Using Infrared for Drying Paint

Infrared paint drying offers significant advantages over traditional methods, making it a valuable asset in the automotive industry, particularly for Mercedes-Benz repairs and automotive body work. One of its key benefits is speed; infrared technology can dry paint quickly, reducing the overall time required for vehicle body repair. This efficiency is crucial in busy workshops where minimizing downtime is essential to meet customer demands.

Additionally, it provides a more consistent and even drying process, ensuring high-quality results. Unlike conventional methods, infrared paint drying avoids surface imperfections like orange peel or uneven texture, which can require additional work and materials for correction. By offering both time and cost savings, this innovative approach is an attractive solution for automotive body repair shops looking to enhance their services and remain competitive in the market.

Reducing Repair Costs: A Case Study

Infrared paint drying has emerged as a game-changer in the automotive collision repair industry, significantly reducing repair costs and streamlining the vehicle bodywork process. This innovative technology is particularly effective in mitigating expenses associated with traditional drying methods. A case study of a recent fender bender illustrates this point perfectly. During the repair process, the use of infrared paint drying resulted in a 20% reduction in labor costs compared to conventional drying techniques.

This efficiency gain can be attributed to the rapid and uniform heating capabilities of infrared technology. By minimizing the time required for paint to dry, technicians are able to complete repairs faster, thereby reducing overhead expenses. Moreover, this method ensures superior results, with improved paint adhesion and a smoother finish, which lowers the likelihood of future repairs and enhances customer satisfaction in automotive collision repair.

Infrared paint drying technology offers a revolutionary approach to reducing repair costs in various industries. By understanding and leveraging its advantages, such as faster drying times, improved paint quality, and minimal surface damage, businesses can significantly cut down on repair expenses. As demonstrated by the case study, adopting infrared paint drying can lead to substantial savings and enhanced efficiency, making it an invaluable asset for any maintenance or construction operation.